Aramid

Aramid, short for aromatic polyamide fibers, can be categorized into para and meta aramid fibers. Kolon manufacture offer para-aramid fibers for numerous applications, depending on types of offering ranging from filament, pulp, staple to spun yarns. We aim to solidify the position as the world's third largest para-aramid manufacturer through production expansion scheduled to complete in 2024.

Global Top 3, Korea's No.1 Para-aramid maker

Various certifications

Quality related IATF16949, ISO14001, etc. Authentication and green related certifications (Oeko-tex, etc.)

Applications

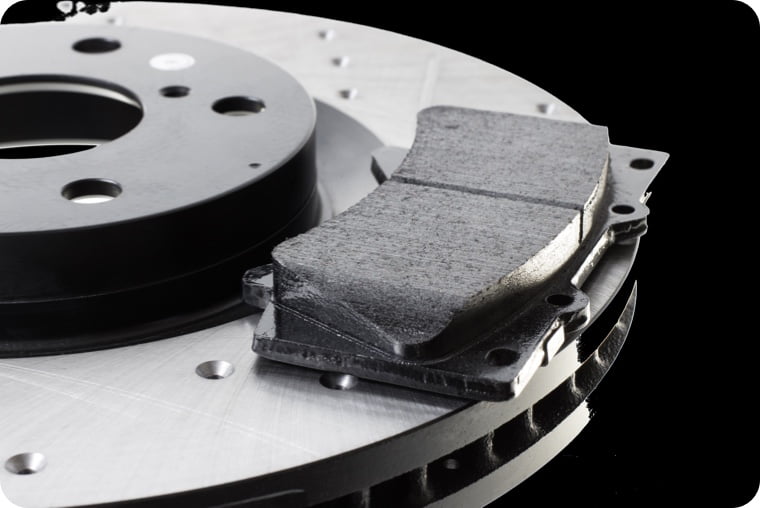

Automotive

Hose, belt, tire cord, brake pad, Lining, clutch, gasket

Safety and Protection

Bullet-proof vests, helmets,plates, military vehicles, firefighting suits,heat-resistant clothing, personal protective garments and gloves

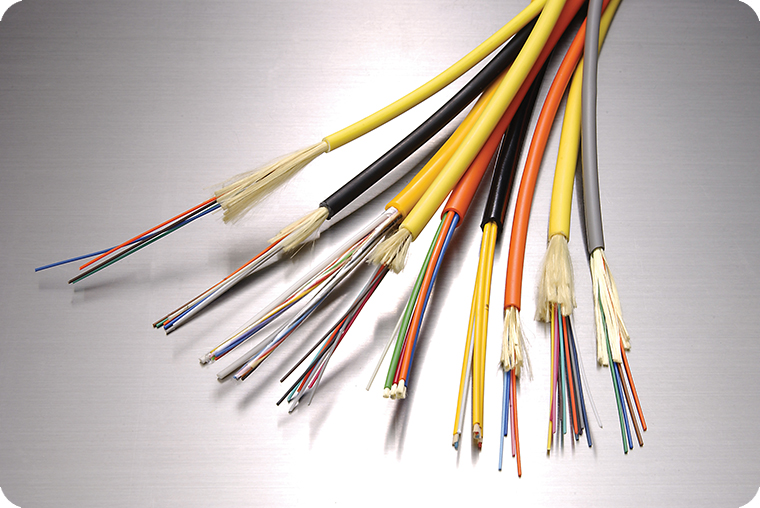

Industrial

Fiber optic cable, deep sea cable, rope, packing, reinforcing material

Composites

Aircraft, shipbuilding, FRP, insulation material, civil engineering, sporting goods

Properties

Excellent mechanical strength

Tensile strength is 6 times higher than that of steel, which is very strong compared to weight and has 4 times higher elasticity than steel, so its shape stability is also very high due to low deformation caused by external factors.

High heat resistance properties

Used as an alternative to ferrous or nonferrous metal materials in a variety of areas requiring heat resistance with a decomposition temperature of 570℃

Self-extinguishing organic material with LOI of 29 or higher and no flame propagation during normal oxygen concentrations

Special electrical and chemical properties

Excellent chemical resistance which is not decomposed by general acid/alkali components and has excellent radio wave transmission characteristics, therefore used in various industrial fields.

Excellent physical properties

Excellent impact resistance, therefore used as material for automobile back beams and bumpers, and also has high wear resistance which allows application to various types of gears

코오롱인더스트리의 모바일 웹은

세로 화면에 최적화되어있습니다